Heavy-Duty Steel Cable Drums for Industrial Applications

Heavy-Duty Steel Cable Drums for Industrial Applications

Steel Cable Drums

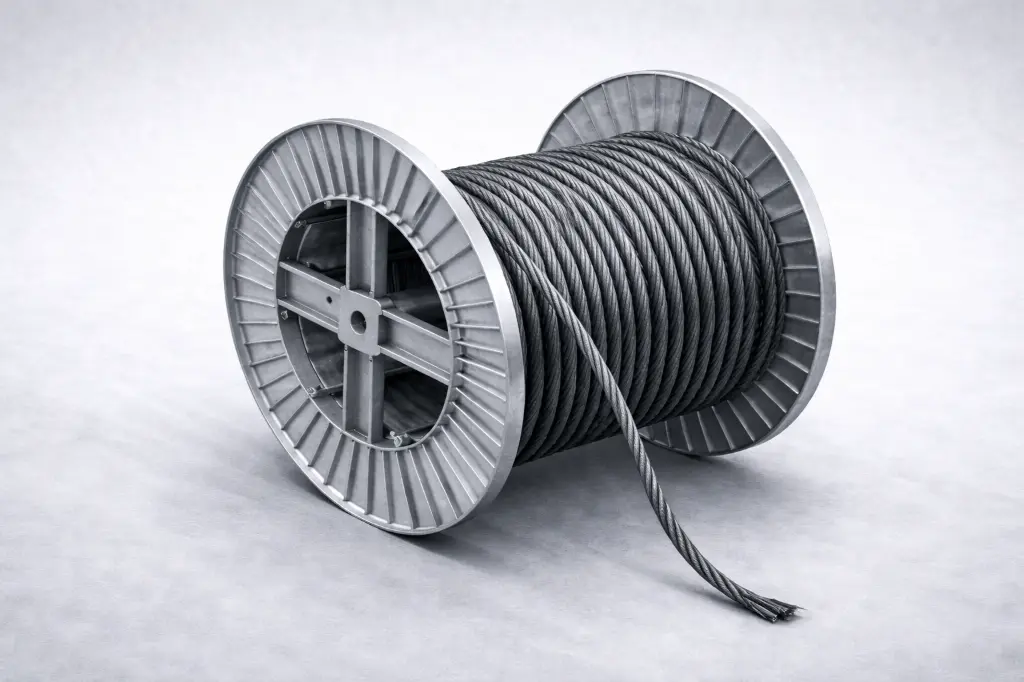

Our Steel Cable Drums have been designed to operate on the high-load industrial cable handling and they are designed with great strength, durability as well as precise winding. The cable drums are made of solid mild steel with tapered flange geometry and are suggested to use with power cables, industrial wiring, mining and cable reeling systems.

We produce corrugated or flat flange (welded + nut and bolted steel cable drums) fully welded and welded + nut and bolted, depending on the operation requirements.

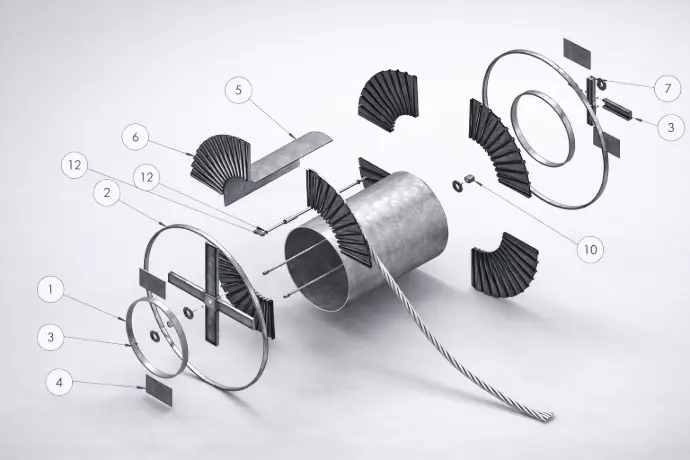

Product Construction & Components

Flange: The flanges are made of corrugated or plain steel with tapered profile to wind cables.

Outer Ring: Enhances the periphery of the flange and prevents deformation under compression.

Inner Ring: This is used to reinforce the structure at the hub region to transfer load.

Inner Drum (Barrel): This is a cylindrical surface with cables wound tightly and safely.

Tie Rods, Nuts and Tie Channels: Ensure structural integrity and keep drums in place.

Central C-Channel Assembly: Coat of arms both the torsional and axial strength of the drum.

MS Strengthening Plates: Strengthening of high stress parts to prevent deformations.

Spindle Bush: This is a machined bush that is used to have the shaft mounted and turned correctly.

- Flange: The flanges are made of corrugated or plain steel with tapered profile to wind cables.

- Outer Ring: Enhances the periphery of the flange and prevents deformation under compression.

- Inner Ring: This is used to reinforce the structure at the hub region to transfer load.

- Inner Drum (Barrel): This is a cylindrical surface with cables wound tightly and safely.

- Tie Rods, Nuts and Tie Channels: Ensure structural integrity and keep drums in place.

- Central C-Channel Assembly: Coat of arms both the torsional and axial strength of the drum.

- MS Strengthening Plates: Strengthening of high stress parts to prevent deformations.

- Spindle Bush: This is a machined bush that is used to have the shaft mounted and turned correctly.

Key Benefits of Our Steel Cable Drums

Construction with Solid Steel

Heavy-weight solid steel construction designed to ensure durability and long-lasting performance, even in harsh environments.

Smooth Cable Layer Tapered Flanges

The tapered flanges provide a smooth and efficient layering for cables, ensuring stability and reducing wear and tear.

Corrugated and Flat Flanged

Offering a choice between corrugated and flat flanged designs, ensuring versatility for a wide range of applications.

Transportable, Storable & Reelable

Easily transportable and storable, designed for convenient reelability, offering high utility for long-distance storage and transport.

Designed for Heavy Cables

Built to work efficiently with long-length and heavy cables, making them perfect for large-scale projects.

Pre-Designed Solutions Offered

We offer pre-designed solutions that can be customized according to project needs, ensuring quick deployment and minimal effort.

Technical Specifications – Steel Cable Drums

General Construction Details (Common for All Types)

| Parameter | Specification |

|---|---|

| Product Type | Heavy-Duty Steel Cable Drum |

| Material | Mild Steel (MS) |

| Construction Options | Fully Welded / Welded + Nut & Bolted |

| Flange Design | Tapered Flanges / Flat Flanges |

| Application | Industrial Cable Storage, Transport & Reeling |

| Surface Finish | Industrial Paint / Epoxy / Hot-Dip Galvanized (Optional) |

| Customization | Available as per cable size & load |

Types of Steel Cable Drums

Type 1 – Corrugated Flange Steel Cable Drum

The corrugated flange steel cable drum is designed with high load and dynamic industrial applications, thus better in stiffness and long-term performance.

| Parameter | Specification |

|---|---|

| Flange Type | Corrugated Steel |

| Inner Width (Drum Face Width) | 1800 mm |

| Outer Diameter (Flange OD) | 2830 mm |

| Inner Diameter (Barrel ID) | 1300 mm |

| Cable Diameter Considered | 20 mm |

| Theoretical Cable Capacity | ≈ 28,400 meters |

| Practical Cable Capacity (90%) | ≈ 25,500 – 26,000 meters |

| Corrugation Profiles | 44 Profiles |

| Flange Geometry | Dual Tapered (Profile & Lengthwise) |

| Construction Type | Welded + Nut & Bolted |

| Load Rating | Heavy-Duty |

| Reusability | High |

Recommended Applications

| Application | Suitability |

|---|---|

| HV / MV Power Cables | ✔ |

| Heavy Industrial Cables | ✔ |

| Cable Reeling Systems | ✔ |

| Mining & Infrastructure Projects | ✔ |

Contact Us

Looking for a custom steel cable drum for your industrial use?

Call us today with your cable diameter, weight and conditions of usage, and our engineering team would come up with an efficient solution.

Type 2 – Flat Flange Steel Cable Drum

The flat flange steel cable drum is an affordable and strong method of cable storage and transportation.

| Parameter | Specification |

|---|---|

| Flange Type | Flat Steel Plate |

| Inner Width (Drum Face Width) | 1800 mm |

| Outer Diameter (Flange OD) | 2830 mm |

| Inner Diameter (Barrel ID) | 1300 mm |

| Cable Diameter Considered | 20 mm |

| Theoretical Cable Capacity | ≈ 28,400 meters |

| Practical Cable Capacity (90%) | ≈ 25,500 – 26,000 meters |

| Reinforcement Type | SHS Tube |

| SHS Size | 30 × 30 × 3 mm |

| Reinforcement Quantity | 8 Nos |

| Flange Geometry | Tapered |

| Construction Type | Fully Welded |

| Load Rating | Medium to Heavy Duty |

Recommended Applications

| Application | Suitability |

|---|---|

| Cable Storage & Transportation | ✔ |

| LV / MV Power Cables | ✔ |

| Static / Low-Rotation Use | ✔ |

| Cost-Optimized Industrial Projects | ✔ |

Surface Treatment & Customization

| Option | Availability |

|---|---|

| Industrial Painting | ✔ |

| Epoxy Coating | ✔ |

| Hot-Dip Galvanizing | Optional |

| Custom Dimensions | ✔ |

| Custom Load Capacity | ✔ |

Contact Us

Looking for a custom steel cable drum for your industrial use?

Call us today with your cable diameter, weight and conditions of usage, and our engineering team would come up with an efficient solution.